What is Wire Spray?

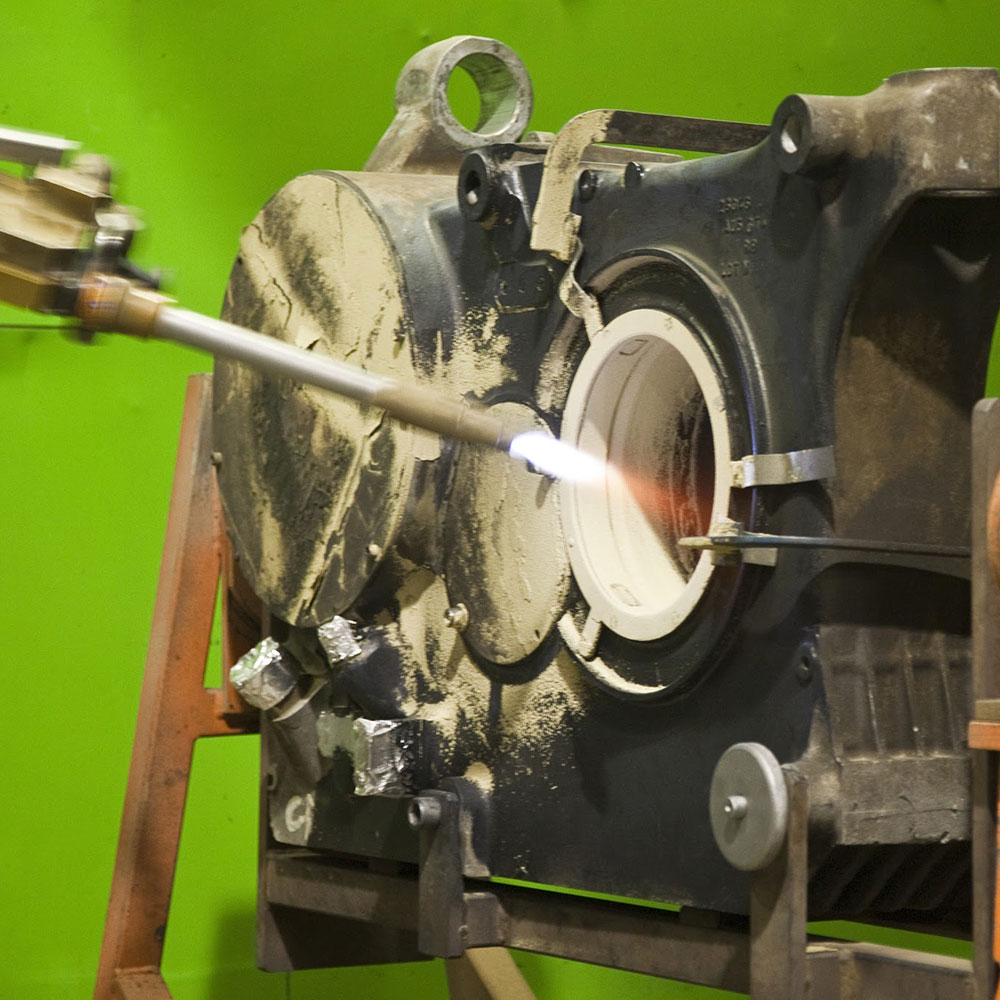

Wire Spray thermal spray is a cost-effective and reliable method used for restoration and surface enhancement in various industries. This technique utilizes a wire feed system, where a metallic wire is melted and propelled onto the substrate to form a protective coating.

Wire Spray is often chosen for its affordability, as it offers a more economical alternative to other thermal spray methods. The wire feed system reduces material waste and enables precise control over the coating thickness, resulting in reduced costs without compromising on quality.

This thermal spray process is particularly effective for restoration purposes. It can be used to repair worn or damaged components, restoring their original dimensions and functionality. Wire Spray coatings exhibit excellent adhesion and provide enhanced resistance to wear, prolonging the service life of the restored parts. Additionally, Wire Spray is compatible with a wide range of materials, including metals and alloys, allowing for versatile applications across industries.

In summary, Wire Spray thermal spray technique offers an affordable and efficient solution for restoration and surface enhancement needs. With its cost-effectiveness, precise control, and restoration capabilities, it provides a reliable method for extending the lifespan of components while maintaining performance and reliability.

Wire spray coating is used in:

Advantages of Wire spray coating

Advantages of Wire Spray Thermal Spray:

- Cost-Effective Solution: Wire Spray thermal spray technique offers a cost-effective coating solution compared to other thermal spray methods. The wire feedstock is relatively inexpensive, making it an economical choice for coating applications.

- Restoration Capability: Wire Spray is particularly beneficial for restoration purposes. It can effectively repair and restore worn or damaged components, extending their service life and avoiding the need for costly replacements.

- Versatile Application: Wire Spray allows for the deposition of various materials, including metals, alloys, and even some ceramics. This versatility enables the coating of a wide range of substrates, providing tailored solutions for different industrial needs.

- Rapid Deposition Rates: The process offers high deposition rates, allowing for efficient and quick coating application. This makes Wire Spray suitable for large-scale projects where time is of the essence.

- Portable and Field Applicable: Wire Spray equipment is often portable, allowing for on-site applications. This feature is advantageous in situations where bringing the workpiece to a dedicated coating facility is not feasible.

In summary, Wire Spray thermal spray technique offers cost-effective coating solutions, restoration capabilities, versatility in material selection, rapid deposition rates, and portability, making it an advantageous choice for various

Results

Bring us your problems, our experience will provide the answers

We support and advise you in selecting the most suitable technology and materials to meet your specific needs.

Contact us now to have an engineer at your disposal, and together, we’ll find the solution to your biggest problems. We understand urgent, an engineer can be immediately available, call us, email us, and if necessary, you’ll have a proposal within 24 hours.

Wire Spray Thermal Spray Technique - F.A.Q.

Yes, Wire Spray Thermal Spray is known for its cost-effectiveness. Compared to other thermal spray methods, wire spray uses inexpensive wire feedstock, making it a more economical option for coating applications.

Absolutely! Wire Spray is commonly used for restoration and repair of worn or damaged components. It can rebuild surfaces, restore dimensions, and enhance the functionality of various industrial parts, extending their service life.

Wire Spray does have some limitations when compared to HVOF:

Coating Quality: Wire Spray coatings may have slightly lower density and porosity levels compared to HVOF coatings, which can affect their resistance to wear and corrosion.

Lower Velocity: Wire Spray typically operates at lower particle velocities compared to HVOF, resulting in lower coating bond strength and potential limitations in certain high-stress applications.

Finishing Requirements: Wire Spray coatings often require additional finishing steps, such as grinding or machining, to achieve the desired surface smoothness, which may increase overall processing time.

In summary, Wire Spray Thermal Spray is an affordable option for coatings and offers excellent restoration capabilities. However, it may have some disadvantages compared to HVOF, including differences in coating quality, particle velocity, and additional finishing requirements.